Short Trident

Oak Wood, Beeswax, Brazilian Carnauba Wax, Mineral Oil

Total Time: 2 Days

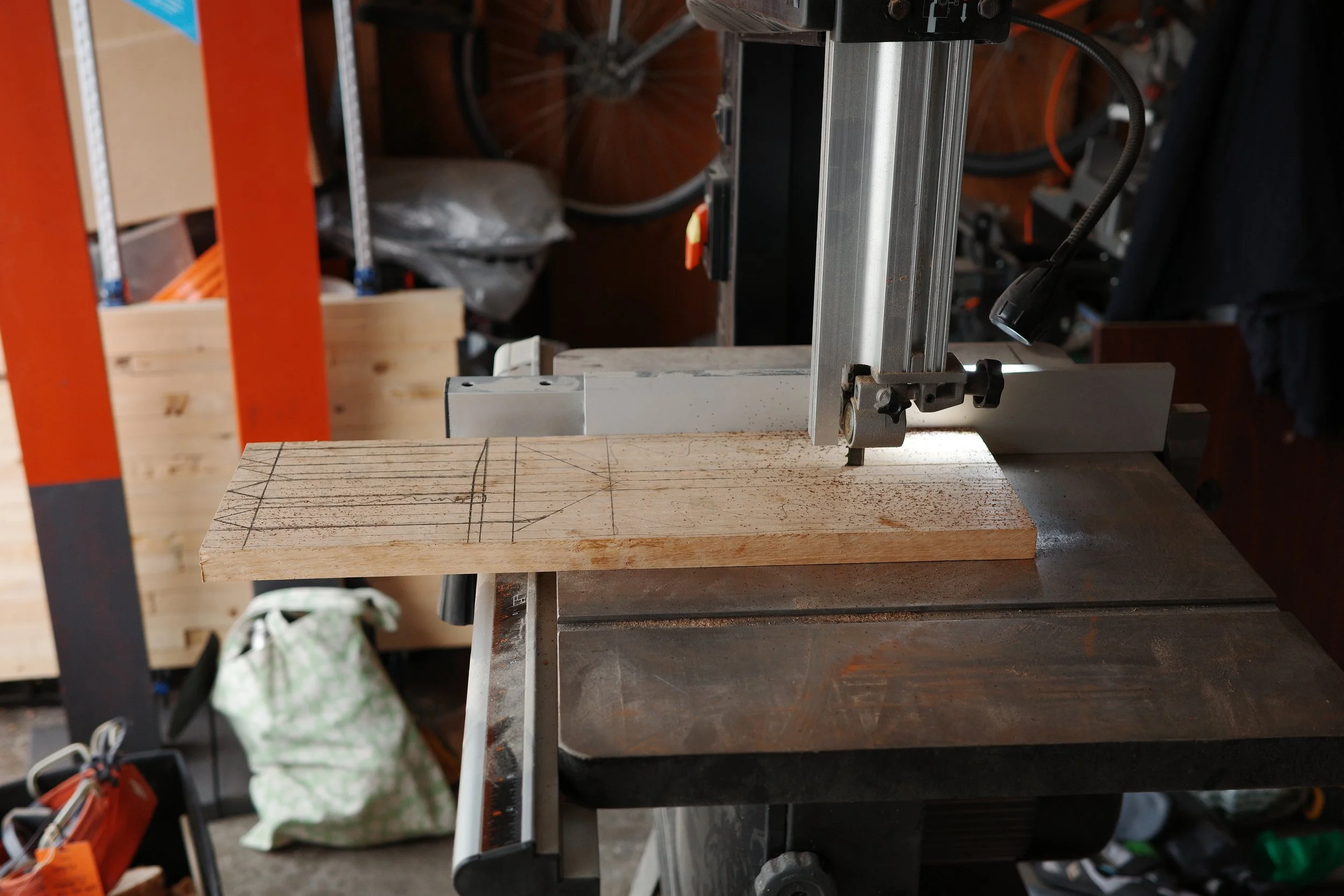

Day One: Ideation and Marking

Digging through a pile of off-cuts, I found a plank that had a nice heft and a rigidity. While inspecting the pattern, I drew the rough shape with some rulers and eyeballed the proportions. I was inspired by the abstract idea of forging the wood plank. In the same way a blacksmith uses a hammer to freely manipulate a piece of metal, I wanted to use minimal tools to draw out the tridents shape.

Day Two: Drill, Cut, Sand, Finish

I first drilled holes at the base between each prong. This was done with a drill bit that was closest in diameter to the drawing. Then, using a band saw, I cut the gaps between each prong. This was the most efficient way for me to remove excess material.

The orbital sander would serve as my hammer in the forging of the trident so sanding was crucial and also the most time consuming. Shaping by hand sanding also allowed me more intimacy with the trident and I was able to fine tune the ergonomics to my hand. Subtle ridges would catch on the specific grooves of my hand and the oblong circumference, akin to a knife handle, filled out my grip in a way that inspired confidence.

To bring out the woods natural beauty and make the grain pop I used a butchers block mixture containing Beeswax, Brazilian Carnauba Wax, Mineral Oil. I prefer this blend because it contains mostly natural and food-safe ingredients. I also feel that the difference in viscosity of each ingredient penetrates to different layers of the wood, providing better preservation. The mineral oil being the thinnest would penetrate deepest and would be held in place in the deeper layers by the waxes above it.